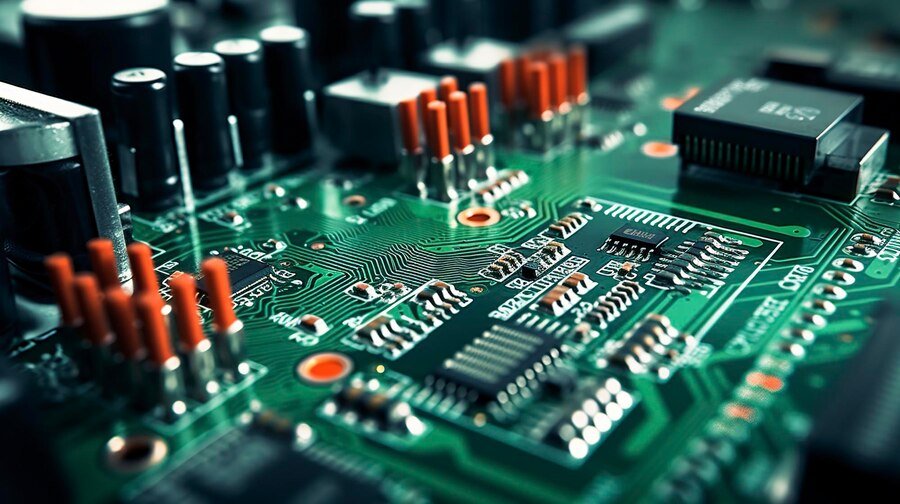

In the realm of electronic component manufacturing precision tools play a pivotal role in ensuring high-quality outputs. One such indispensable tool is the Kurt Vise by 5th Axis renowned for its robustness and precision. Kurt Adapter Vises are specifically designed to handle the intricacies involved in securing components during the delicate processes of machining and assembly.

Improving CNC Machine Performance with Precision Adapter Plates

Adapter plates are a crucial component in the utilization of Kurt Vises, especially in settings that involve CNC machines. These plates allow the vise to be adapted to various machine surfaces thereby increasing the versatility and functionality of the equipment. The precision with which these adapter plates are manufactured directly impacts the overall accuracy of the machining process as they ensure that the vise remains stable and aligned during operations.

Advantages of Using Kurt Vise in CNC Operations

When it comes to CNC machining the stability of the setup is key to achieving precise cuts and detailed component fabrication. Kurt Machine Vise adapter plates contribute significantly by providing a secure mounting surface that resists vibrations and movement. This stability is crucial for operations that require high levels of precision such as the creation of intricate electronic components where even a micron’s deviation can lead to product failure.

The Importance of Adapter Plates in Engineering Precision

The engineering behind Kurt Vise adapter plates is focused on precision. Each plate is designed to exact specifications to ensure that it perfectly complements the vise it supports. This synergy between the adapter plate and the vise leads to an enhanced overall performance ensuring that components are held securely without any risk of shifting during the critical manufacturing phases.

Boosting Manufacturing Precision with Quality Adapter Plates

Quality control in electronic component manufacturing is non-negotiable. The precision provided by Kurt Vise adapter plates plays a direct role in ensuring that each component meets strict quality standards. By maintaining a firm hold on components these vises minimize errors and enhance the reliability of the production process leading to products that consistently meet or exceed expectations.

Read Also: Boosting Productivity with Top-Notch CNC Tools

Streamlining Production with Kurt Vise

Production efficiency is another benefit of integrating Kurt Adapter Vise into CNC machining workflows. The ease of setup and versatility provided by the adapter plates means that changeovers between different manufacturing operations can be done quickly and without compromising on accuracy. This streamlines the entire production process reducing downtime and increasing throughput.

Summing Up

In conclusion, the Kurt Machine Vise and its adapter plates are more than just tools; they are foundational elements that enhance the precision efficiency and quality of electronic component manufacturing. By investing in high-quality Kurt Vise products, manufacturers can ensure that their operations are not only efficient but also capable of producing components that meet the rigorous demands of the technology industry. As we move forward into an era where precision is at a premium, tools like Kurt Adapter Vise will continue to play a critical role in manufacturing success.